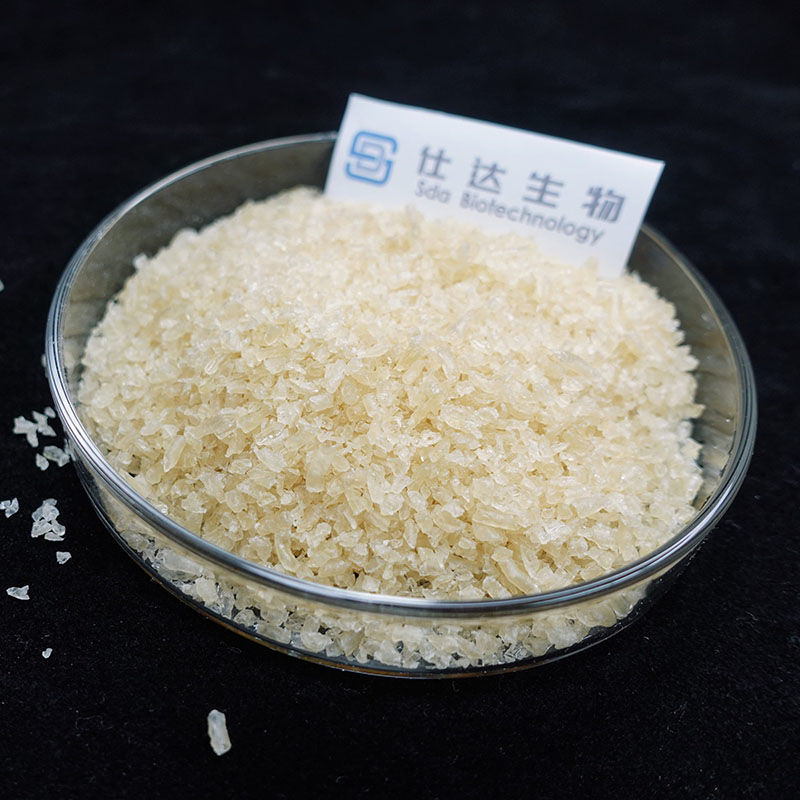

Gelatin-Microcapsule

• Protective active ingredient

• Wide application scenarios

Additional information

Weight: 25 kg

Dimensions: 90 × 45 × 10 cm

Key word:

Download:

Gelatin’s Application In Microcapsule

Gelatin, as a natural biopolymer material, has biodegradability, good biocompatibility and gelatinability, and is widely used as a medicinal excipient in the field of medicine.、

A microcapsule is a microcontainer or package with a polymer shell.

Gelatin is widely used in microcapsule technology, mainly for the formation of microcapsule wall material. Microencapsulation technology is a method of encasing core materials such as liquids, solids or gases to form tiny particles, and gelatin is an important wall material choice because of its unique physical and chemical properties.

The advantage of gelatin as microcapsule wall material

Good film formation

Gelatin can form a continuous film under certain conditions, which helps to wrap the core material and form stable microcapsules.

Biocompatibility and safety

As a natural polymer, gelatin is harmless to the human body and can be used in food, medicine and cosmetics.

Heat sensitivity

The gelation and dissolution properties of gelatin are temperature sensitive, facilitating the release of core substances under specific conditions.

Regulated release performance

Gelatin in combination with other wall materials, such as gum Arabic or sodium alginate, can regulate the release rate of microcapsules.

A wide range of microcapsules

After the special core material is microencapsulated, its color, shape, volume, quality, solubility and storage will change to a certain extent, under specific conditions, the core material will be slowly released to play a role.

USAGE:

The gelatin particles and water, according to 1:10, that is 1 part of gelatin powder and 10 parts of cold water soak, (the proportion of adding water can be adjusted according to the production process) 40-60 minutes, after the expansion of water absorption and then indirect heating dissolved, the sol can not be directly heated, the sol temperature is controlled below 80℃, completely heated dissolved into the glue state can be added and used.

The Optional Particle Size Is:

| 0.3mm 60 mesh fine grinding | 0.5mm 35 mesh fine grinding | 0.8mm 20 mesh fine grinding | 3mm 8 mesh fine grinding |

GB6783-2013 & Contract Requirements

| Moisture | % | ≤14.0 | 10.0 |

| Gel Strength | Bloom | 6.67% 10℃ | 150-180 |

| Viscosity | °E | 15%,40℃ | 5.0-9.0 |

| mPa.s | 6.67%,60℃ | 3.0-4.0 | |

| Light transmittanceratio | % | Wavelength450nm≥30 Wavelength620nm≥50 |

Wavelength450nm:81 Wavelength620nm:92 |

| Chromium(in Cr) | mg/kg | ≤2.0 | 0.5 |

| Total Bacterial Count | CFU/g | ≤10000 | <100 |

Recommended Products

Sample Application

Attention: Please leave your contact information, and our professionals will contact you as soon as possible!